In today's highly competitive global business landscape, making the right choices when sourcing products is crucial for the success and growth of any enterprise. Acrylic products have gained significant popularity due to their versatility, durability, and aesthetic appeal. When considering acrylic manufacturing partners, China has emerged as a leading destination. Here are the top 10 reasons why choosing a China acrylic manufacturer can transform your business.

1. China Acrylic Manufacturers Have a Cost Advantage

As a world manufacturing power, China has a significant cost advantage in acrylic manufacturing.

First, China's huge labor pool makes labor costs relatively low.

Each link in the production process of acrylic products, from the preliminary processing of raw materials to the fine assembly of finished products, requires a lot of human input. Chinese manufacturers can do this with relatively economical labor costs, resulting in substantial savings in overall production costs.

In addition, China's well-established supply chain system is also an important source of cost advantages.

China has formed a large and efficient industrial cluster in the production and supply of acrylic raw materials. Whether it is the production of acrylic sheets, or a variety of supporting glue, hardware accessories, etc., can be obtained at a relatively low price in China. This one-stop supply chain service not only reduces the logistics cost and time cost of the procurement link but also further reduces the unit cost through the large-scale procurement of raw materials.

Taking an acrylic display rack enterprise as an example, due to the convenient purchase of high-quality and reasonably priced acrylic sheets and related accessories in China, its production cost is reduced by about 20%-30% compared with peers who purchase raw materials in other countries. This allows enterprises to have more flexibility in the market pricing, which can not only ensure the profit space of the product but also provide competitive prices, to occupy a favorable position in the market competition.

2. China Acrylic Manufacturers Have Rich Production Experience

China has a deep historical background and rich production experience in the field of acrylic manufacturing.

As early as several decades ago, China began to be involved in the production of acrylic products, from the initial simple acrylic products, such as plastic stationery, simple household items, etc., gradually developed to now be able to produce a variety of complex high-end customized acrylic products.

Years of practical experience have made Chinese manufacturers more and more mature in acrylic processing technology. They are skilled in various acrylic molding techniques, such as injection molding, extrusion molding, hot bending molding, etc.

In the connection process of acrylic, glue bonding can be used freely to ensure that the connection of the product is firm and beautiful. For example, in the production of a large acrylic aquarium, multiple acrylic sheets need to be precisely stitched together. Chinese manufacturers, with their superb hot bending and bonding technology, can create a seamless, high-strength, and highly transparent aquarium, providing a near-perfect living environment for ornamental fish.

3. China Acrylic Manufacturers Have a Variety of Product Choices

China acrylic manufacturers can provide a variety of product choices. Whether it is the acrylic display stand, acrylic display boxes in the field of commercial display; acrylic storage boxes, acrylic vases and photo frames in home decoration, or acrylic trays in the service field, it has everything. This rich product line covers almost all industry needs for acrylic products.

What's more, Chinese acrylic manufacturers also provide highly customized services.

Enterprise customers can put forward personalized design requirements according to their own brand image, product characteristics, and display needs.

Whether it is a unique shape, special color, or customized function, Chinese acrylic manufacturers are able to turn customers' ideas into reality with their strong design and production capabilities.

If You Are in business,You May Like:

4. China Acrylic Manufacturers Have Advanced Production Technology and Equipment

China's acrylic manufacturers have always kept pace with the times in terms of production technology and equipment. They actively introduce and develop advanced acrylic processing technology to meet the market requirements for high precision and high-quality products.

In cutting technology, high-precision laser cutting equipment has been widely used. Laser cutting can achieve accurate cutting of acrylic sheets, smooth and smooth incisions, and no burr, greatly improving the processing accuracy of products. Whether it is a complex curve shape or a tiny hole, laser cutting can easily deal with it.

CNC molding technology is also a big advantage for Chinese manufacturers. Through numerical control equipment, acrylic sheets can be accurately bent, stretched, and compressed into a variety of complex shapes. In the production of acrylic decorative parts for automobile interiors, CNC molding technology can ensure the perfect match between the decorative parts and the interior space of the automobile, and improve the assembly efficiency and quality of the products.

In addition, Chinese manufacturers are constantly exploring new joining and surface treatment technologies. For example, seamless splicing technology makes acrylic products more beautiful and generous in appearance, eliminating gaps and defects that may be left by traditional connection methods. In terms of surface treatment, the special coating process, can enhance the wear resistance, corrosion resistance, and fingerprint resistance of acrylic products, prolong the service life of the product, and improve its appearance and texture.

At the same time, Chinese manufacturers have invested heavily in upgrading their production equipment. They maintain close cooperation with internationally renowned equipment manufacturers, timely introduction of the latest production equipment, and optimization and upgrading of existing equipment. This not only ensures the continuous improvement of production efficiency but also enables product quality to always be at the leading level in the industry.

5. China Acrylic Manufacturers Have Efficient Production Capacity and Delivery Speed

China's vast manufacturing infrastructure has given acrylic manufacturers strong production capacity.

The numerous production plants, advanced production equipment, and abundant human resources enable them to undertake large-scale order production tasks.

Whether it is a large-scale enterprise procurement project that requires tens of thousands of acrylic products at one time, or a long-term stable batch order, China manufacturers can organize production efficiently.

Take the acrylic promotional gift box order of an international supermarket chain as an example, the order quantity is up to 100,000 pieces, and the delivery is required to be completed within two months. With their perfect production planning and scheduling system and sufficient production resources, China manufacturers quickly arrange all aspects of raw material procurement, production scheduling, quality testing, and so on. Through the parallel operation of multiple production lines and reasonable process optimization, the order was finally delivered one week ahead of schedule, which ensured that the promotion activities of the supermarket could be carried out smoothly on time.

China manufacturers are also doing well in responding to rush orders. They have flexible production scheduling mechanisms that allow them to quickly adjust production plans and prioritize the production of urgent orders.

For example, on the eve of a new product launch, an electronic technology company suddenly found that the originally planned acrylic product packaging had a design flaw and needed to urgently re-produce a new batch of packaging. Upon receiving the order, the China manufacturer immediately initiated an emergency production process, deployed a dedicated production team and equipment, worked overtime, and completed the production and delivery of the new packaging in just one week, helping the electronic technology company to avoid the risk of new product launch delays caused by packaging problems.

This efficient production capacity and fast delivery speed have won valuable time advantages for enterprise customers in the market competition. Enterprises can be more flexible to respond to market changes, timely launch new products, or meet temporary market demand, so as to enhance their market competitiveness.

6. China Acrylic Manufacturers Have Strict Quality Control Standards

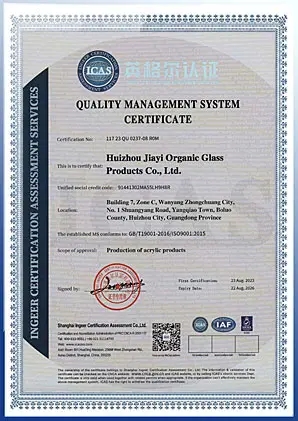

China's acrylic manufacturers are well aware that quality is the cornerstone of enterprise survival and development, so they follow extremely strict standards in quality control. Many enterprises have passed the international authoritative quality certification system, such as ISO 9001 quality management system certification, etc., from raw material procurement, and production process monitoring to finished product inspection, every link is strictly in accordance with the standard operation process.

In the raw material inspection link, the manufacturer adopts advanced testing equipment and methods to strictly test the physical performance indicators of acrylic sheets, including transparency, hardness, tensile strength, weather resistance, etc. Only raw materials that meet quality standards will be allowed to enter the production process.

In the production process, quality control throughout. After each process is completed, there are professional quality inspection personnel to check to ensure that the product meets the process requirements. For key processes, such as the forming of acrylic products, it is a combination of automatic detection equipment and manual detection to comprehensively detect the dimensional accuracy, connection strength, and appearance quality of products.

Finished product inspection is the final level of quality control. Manufacturers use strict sampling inspection methods to conduct comprehensive performance testing and appearance inspection of finished products. In addition to regular physical performance testing, the packaging, marking, etc. of the product are checked to ensure the safety and traceability of the product during transportation and storage.

Only finished products that pass all inspection items will be allowed to leave the factory for sale. This strict quality control standard makes China acrylic products famous for high quality in the international market and has won the trust and recognition of many customers.

7. China Acrylic Manufacturers Have Innovation and Research and Development Capabilities

China acrylic manufacturers have invested a lot of resources in innovation and research and development, and are committed to promoting the innovation and development of acrylic materials and products. They have a professional research and development team, whose members not only have deep knowledge of materials science but also have a keen insight into market trends and customer needs.

In terms of product design innovation, China manufacturers continue to innovate. They combine modern design concepts and emerging technologies to develop a range of innovative acrylic products. For example, the emergence of smart acrylic home products combines the aesthetics of acrylic with smart home technology. An intelligent acrylic coffee table, the desktop is made of transparent acrylic material, a built-in touch control panel, can control the intelligent equipment around the coffee table, such as lighting, sound, etc., but also has a wireless charging function, to provide users with a convenient and fashionable home life experience.

8. Favorable Business Cooperation Environment

China has been committed to creating a good business cooperation environment, which provides a solid guarantee for the cooperation between international enterprises and China acrylic manufacturers. The China government has introduced a series of policies to encourage foreign trade and investment, simplify trade procedures, lower trade barriers, and facilitate trade between international enterprises and Chinese manufacturers.

In terms of business integrity, China acrylic manufacturers generally follow the concept of integrity management. They pay attention to the performance of the contract, strictly in accordance with the terms of the contract to perform the order production, delivery, after-sales service, and other tasks.

In terms of prices, the company will be transparent and fair, and will not arbitrarily change prices or set hidden fees.

In terms of communication, China manufacturers are usually equipped with professional foreign trade teams and customer service personnel, who can communicate smoothly with international customers, reply to customer inquiries and feedback in time, and solve problems encountered by customers in the process of cooperation.

China's Top Custom Acrylic Products Manufacturer

Jayi Acrylic Industry Limited

Jayi, as a leading acrylic product manufacturer in China, has a strong presence in the field of custom acrylic products.

The factory was established in 2004 and has nearly 20 years of experience in customized production.

The factory has a self-constructed factory area of 10,000 square meters, an office area of 500 square meters, and more than 100 employees.

At present, the factory has several production lines, equipped with laser cutting machines, CNC engraving machines, UV printers, and other professional equipment, more than 90 sets, all processes are completed by the factory itself.

Conclusion

The choice of China acrylic manufacturers for enterprises has many advantages that can not be ignored. From cost advantage to rich production experience, from diversified product selection to advanced production technology and equipment, from efficient production capacity and delivery speed to strict quality control standards, China acrylic manufacturers have shown strong competitiveness in all aspects.

In today's global economic integration, if enterprises can make full use of these advantages of China acrylic manufacturers, they will be able to achieve significant improvement in product quality, cost control, market response speed, and other aspects, to stand out in the fierce market competition and achieve the business goal of sustainable development. Whether large multinational enterprises or emerging start-up companies, in acrylic product procurement or cooperation projects, they should seriously consider the China acrylic manufacturers as an ideal partner, and jointly create a win-win business situation.

Post time: Dec-09-2024