In today's business and personal display field, custom acrylic rectangle boxes play an extremely important role. Whether used for exquisite gift packaging, high-end product display or as a unique storage container, these transparent and delicate boxes can attract people's attention and enhance the overall image of the item. However, the process of ordering custom acrylic rectangular boxes can be fraught with confusion for many people. This article will provide you with a detailed step-by-step guide to help you successfully complete your order and ensure that you get a high-quality product that meets your needs.

Step 1: Identify the requirements

It is crucial to clarify your specific needs for custom acrylic rectangle boxes before starting an order.

1. Dimensions:

First, accurately measure the length, width, and height of the items you need to contain in the acrylic box. Use a precise measuring tool, such as a caliper or tape measure, to ensure that the results are accurate. Consider how items are placed inside the box and whether additional space is needed for buffering or decoration.

2. Thickness Requirements:

Acrylic sheets is available in a variety of thicknesses.

Thinner plates are usually lighter and lower cost, and are suitable for some display purposes with low load-bearing requirements, such as the display of small jewelry and cosmetics samples.

Thicker sheets, on the other hand, have better strength and stability and can be used to carry heavier items or in scenarios where more robust structures are required, such as storing tools, models, etc.

Depending on the purpose of the box and the weight it is expected to bear, the appropriate thickness is selected, and generally common thickness ranges from 1 mm to 10 mm.

3. Color and Opacity Preferences

Acrylic can come in various colors, including clear, frosted, and various colors.

Transparent acrylic boxes can maximize the display of internal items, creating a simple, stylish visual effect, often used in high-end product displays or gift packaging, so the item becomes the focus.

The frosted acrylic box can add a soft, hazy aesthetic feeling, suitable for some items with artistic atmosphere or need to create a special atmosphere.

Colorful acrylic boxes can be selected according to the brand color or specific design theme to highlight the brand personality or match the surrounding environment.

When determining color and transparency, consider your brand image, product characteristics, and the overall style of presentation or packaging.

4. Special Design and Functional Requirements:

Consider adding some special designs and features to make your acrylic rectangle box more unique and practical.

For example, carving a brand logo, pattern, or text on the surface of the box can not only play a decorative role but also strengthen the brand.

The built-in partition can divide the internal space of the box, which makes it easy to classify and store different items. For example, in the cosmetics storage box, different kinds of cosmetics can be placed separately.

Magnetic sealing can make the opening and closing of the box more convenient and tight, and improve the use experience. It is often used in some boxes that need to be opened and closed frequently, such as high-end gift boxes.

Special corner treatment, such as a rounded design, can avoid the harm caused by sharp corners to the user but also can give the box a more rounded, delicate appearance, suitable for children's product packaging or safety-conscious scenes.

Step 2: Find Acrylic Rectangle Box Manufacturers

After determining the requirements, the next crucial step is to find the right manufacturer.

1. Online Search Channels:

Using the mainstream search engine, input relevant keywords, such as "custom acrylic rectangle box manufacturer", "custom acrylic rectangle box manufacturer", etc., and the search engine will show you a large number of supplier websites, e-commerce platforms stores, and industry information pages.

On the e-commerce platform, you can directly view product details, customer reviews, price ranges, and other information about different suppliers, which is convenient for preliminary screening. At the same time, the industry professional website usually brings together many high-quality supplier resources and provides some industry standards, technical articles, and other reference materials, to help you to understand the acrylic box customization industry.

When browsing supplier websites, focus on their product display pages to see if there are cases similar to your needs, as well as descriptions of the manufacturing processes and materials they use.

2. Offline Reference:

Attending all kinds of packaging, gifts, and crafts exhibitions is a great opportunity to communicate with suppliers directly and face-to-face.

At the exhibition, you can observe the product samples displayed by the suppliers on the spot, and intuitively feel their quality and technology level. Communicate with the supplier's sales staff to get detailed information about their production capacity, custom service process, pricing strategy, etc.

In addition, asking for recommendations from peers, friends, or people in the industry is also a reliable method. They may have experience in customizing acrylic boxes and can share some information about quality suppliers they have actually cooperated with, including the advantages of suppliers, precautions in the cooperation process, etc., which can help you avoid detours and quickly find a reputable supplier.

3. Key Points for Manufacturer Evaluation:

Several key factors need to be evaluated when screening manufacturers.

Product quality is of primary concern. Look at the manufacturer's past case studies to see how their customized acrylic boxes for other customers have performed in terms of dimensional accuracy, material texture, process details, and more. Manufacturers can be asked to provide samples, and their quality level can be assessed by the actual inspection of the samples.

Production capacity is also important to ensure that suppliers are able to meet your order quantity requirements and complete production within your expected delivery period. Ask about their production equipment, staffing, and production process management to determine their production efficiency and stability.

The rationality of the price is also important. Compare the quotations of different suppliers, but not only look at the price but also analyze the price composition. Some suppliers may offer lower prices but may be lacking in material quality, workmanship standards, or after-sales service.

Finally, understand the supplier's after-sales service policy, such as whether to provide after-sales maintenance, return, and replacement services, how to deal with product quality problems, etc., perfect after-sales service can provide a strong guarantee for your ordering process.

Step 3: Get the Offer and Negotiate Details

Once a potential manufacturer has been found, it is necessary to contact them to obtain a quote and negotiate the relevant details.

1. Contact Manufacturer and Provide Requirement Information:

When contacting the manufacturer, clearly and accurately communicate to them the detailed requirements of the box size, thickness, color, design, etc. that you have previously determined.

Communication can be done via email, phone, or online customer service. When providing requirements information, try to use specific data and descriptions to avoid ambiguous statements.

For example, it is clear that the length, width, and height of the acrylic rectangular box are accurate to millimeters, the color is numbered by an international standard color card (such as a Pantone color card), and the design pattern is provided in a vector map file (such as AI and EPS format). This helps the manufacturer quickly and accurately calculate your cost and provide you with a quote.

2. Understand What Constitutes an Offer:

The offer provided by the manufacturer usually contains multiple parts.

Material cost is an important part of it, acrylic sheet quality, thickness, size, and market price fluctuations will affect the cost of materials.

The processing cost covers the cost of a series of production and processing processes such as cutting, grinding, carving, g, and assembly. Complex design and process requirements will lead to increased processing costs.

Shipping costs depend on your shipping address, order quantity, and shipping method (e.g. express, logistics).

In addition, there may be some other costs, such as packaging costs, taxes, etc.

Knowing what constitutes a quote will help you understand the reasons for price differences and be more targeted when negotiating with the manufacturer.

3. Negotiate Price and Terms:

There are a few tricks you can use when negotiating prices with manufacturers.

If your order is large, try negotiating a bulk purchase discount with the manufacturer. Show your long-term cooperation intention, let the manufacturer see the future business potential, they may give a certain discount on the price.

For lead times, negotiate flexible arrangements with suppliers based on your actual needs. If you have more time, you can extend the delivery period appropriately, and the manufacturer may reduce the cost and make a concession on the price.

At the same time, in the negotiation process, the quality assurance clause is clarified, and the manufacturer is required to promise to be responsible for the quality of the product within a certain period, such as free repair or replacement in case of quality problems.

The payment method is also an important part of the negotiation. The common payment methods include advance payment, installment payment, etc., so choose a payment method acceptable to both parties to ensure the smooth progress of the transaction.

Step 4: Acrylic Rectangle Box Design Confirmation and Sample Production

After reaching a preliminary agreement with the manufacturer on the price and terms, enter the design confirmation and sample production.

1. Review of the First Design Draft:

After a manufacturer produces a first draft of the design to your needs, you need to review it from multiple perspectives.

From a visual point of view, whether the design meets your aesthetic expectations, color matching, or pattern layout is coordinated and beautiful.

From the functional point of view, whether the design meets the actual use needs of the box, such as whether the position of the partition is reasonable, whether the opening way is convenient, etc.

Also make sure that the design is consistent with your brand image and that the brand logo, fonts, colors, and other elements are accurately represented in the design.

If you are not satisfied with the first draft of the design, submit your comments and suggestions to the manufacturer in time and ask them to adjust it until the design meets your requirements.

2. Sample Production Process and Significance:

Asking the manufacturer to make a sample is a very important step.

The sample production process generally includes material preparation, cutting processing, assembly molding, and other links according to the final design scheme. This process usually takes a certain amount of time, generally about 3-7 days, and the specific time depends on the complexity of the design and the manufacturer's production schedule.

There may be a cost to make the sample, which can range from tens to hundreds of dollars, depending on the complexity of the sample and the cost of materials.

Through the sample, you can intuitively feel the actual effect of the box, including whether the size is appropriate, whether the color is accurate, whether the process details are delicate, etc., to find problems and make adjustments before mass production, to avoid quality problems after mass production and cause greater losses.

3. Sample Evaluation and Adjustment:

After receiving the sample, a thorough and detailed evaluation is carried out.

Use the measuring tool to check the size accuracy of the box, whether it is consistent with the size you require, and whether the error is within an acceptable range. Compare the color of the sample with the color you expect to see if there is a color difference. Check the details of the process, such as the smooth grinding of edges and corners, the clear pattern of carving, and the firm assembly.

If any problem is found, such as size deviation, color discrepancy, workmanship defects, etc., communicate with the manufacturer immediately, explain the problem in detail, and negotiate the adjustment plan. Manufacturers may need to readjust production processes, change materials, or fine-tune the design to ensure that the final product meets your quality standards.

Step 5: Order and Production Follow-Up

After the acrylic rectangle box sample is confirmed to be correct, you can sign a contract with the supplier and place an order for production.

1. Sign the Contract:

Signing a formal contract is an important part of protecting the rights and interests of both parties.

The contract should specify the detailed specifications of the product, including size, thickness, color, design requirements, etc., to ensure that the manufacturer produces to your requirements.

The price clause should be clear and clear, indicating the unit price of the product, the total price, the method of payment, and whether it includes freight, taxes, and other expenses.

The quantity clause determines the specific quantity of the order to avoid the occurrence of quantity disputes.

Delivery time specifies the specific time when the supplier will deliver the product and the liability for breach of contract for late delivery.

Quality standards describe in detail the quality requirements that a product should meet, such as material quality standards, process standards, appearance quality standards, etc., and specify inspection methods and treatment methods for nonconforming products during quality acceptance.

In addition, the contract should also contain the rights and obligations of both parties, confidentiality clauses, dispute resolution methods, and other contents to ensure that any problems in the transaction process are per the rules.

2. Production Schedule Tracking:

After the order is placed, it is crucial to keep a close track of the production progress.

We can communicate with the manufacturer regularly to know the progress of each stage of production.

The manufacturer is required to provide photos or video updates during the production process to visually view the actual situation at the production site, such as material processing, assembly links, etc.

Establish inspection mechanisms at key time points, such as completion of material purchase, completion of major processing steps, start of assembly, etc., to ensure that production is on schedule.

If the production schedule is delayed or other problems occur, timely negotiate with the manufacturer for solutions, such as adjusting the production plan, increasing the investment of manpower or equipment, etc., to ensure that the products can be delivered on time.

Step 6: Acrylic Rectangle Box Quality Inspection and Acceptance

After the acrylic rectangle box sample is confirmed to be correct, you can sign a contract with the supplier and place an order for production.

1. Quality Inspection Standards and Methods:

The quality standard for acceptance shall be specified in the contract.

For the quality of acrylic materials, check whether its hardness meets the requirements, you can use hardness testing instruments for testing.

Transparency should be of the desired standard, with no apparent turbidity or blemishes, as can be determined by visual inspection.

In terms of flatness, observe whether the surface of the box is smooth and there is no uneven phenomenon, and the box can be placed on a horizontal plane for inspection.

The assembly firmness of the box was tested by gently shaking and pressing to ensure that the various components were connected tightly and there was no sign of loosening. The edges and corners should be smooth and rounded, without sharp edges and corners, and can be felt by hand.

For carving, printing, and other process details, check whether the pattern is clear and complete and whether the color is uniform.

In the inspection process, use the corresponding measurement tools and inspection equipment, and record the inspection results truthfully, so as to compare with the contract requirements.

2. Acceptance Process and Matters Needing Attention:

When receiving goods, first check whether the quantity of goods is consistent with the order and check the packing list.

Check whether the packaging is complete, whether there is no damage, deformation, or other conditions, and if the packaging damage may lead to product damage in the transportation process.

Check the quality of the products against the contract and sample, and check them one by one according to the above quality inspection standards and methods.

If the product is found to have quality problems, such as size discrepancies, quality defects, etc., within the specified time (generally within 3-7 days after receiving the goods), timely raise quality objections to the supplier, and provide a detailed description of the quality problem and relevant evidence, such as photos, inspection reports, etc.

Negotiate solutions with the manufacturer, such as return or replacement, replenishment, maintenance negotiated price discounts, etc., to ensure that their rights and interests are protected.

China's Top Custom Acrylic Rectangle Box Manufacturer

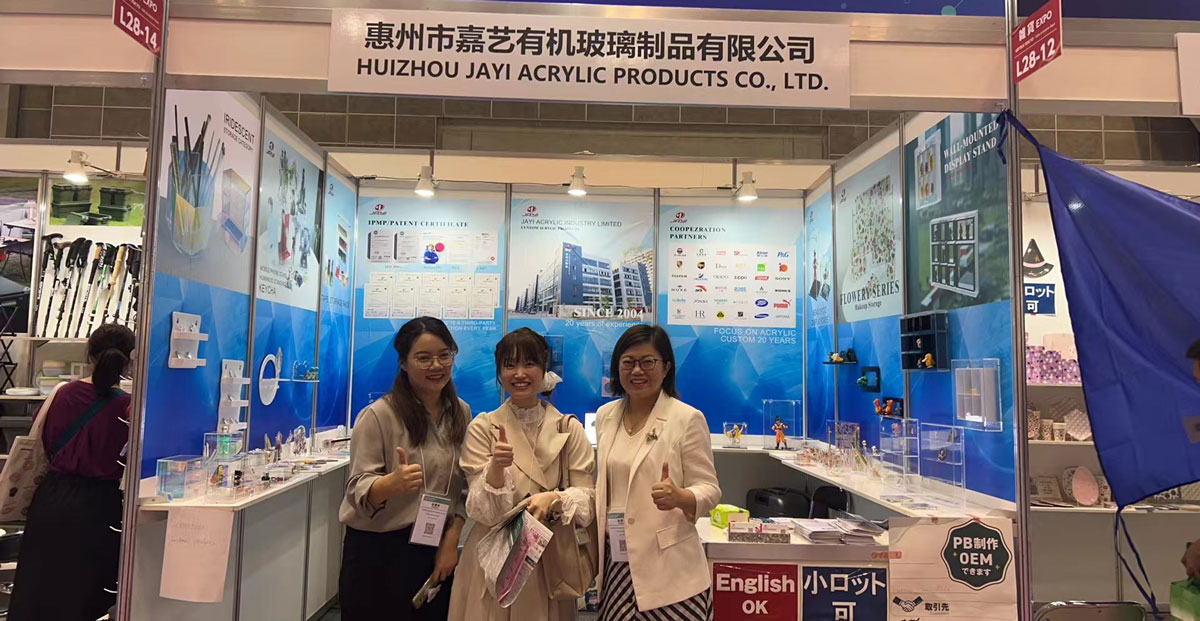

Jayi Acrylic Industry Limited

Jayi, as a leading acrylic product manufacturer in China, has a strong presence in the field of custom acrylic rectangle boxes.

The factory was established in 2004 and has nearly 20 years of experience in customized production.

The factory has a self-constructed factory area of 10,000 square meters, an office area of 500 square meters, and more than 100 employees.

At present, the factory has several production lines, equipped with laser cutting machines, CNC engraving machines, UV printers, and other professional equipment, more than 90 sets, all processes are completed by the factory itself, and the annual output of all kinds of acrylic boxes more than 500,000 pieces.

Conclusion

With the steps detailed above, you have completed your order for custom acrylic rectangle boxes. In the whole process, it is crucial to clarify the requirements, find a suitable manufacturer, negotiate the details, confirm the design, track the production, and strictly accept the acceptance. Summarizing the key points of the ordering process will help you make future orders easier.

More Custom Acrylic Box Cases:

If You Are in business,You May Like:

Post time: Dec-05-2024